Coban Solution

Digital Printing

Coban offers a simple and scalable solution for managing data flow for digital printing.

Digital printing occurs by preparing the data of the points that make up the design,

loading them onto the cards, moving the heads or the media to print them.

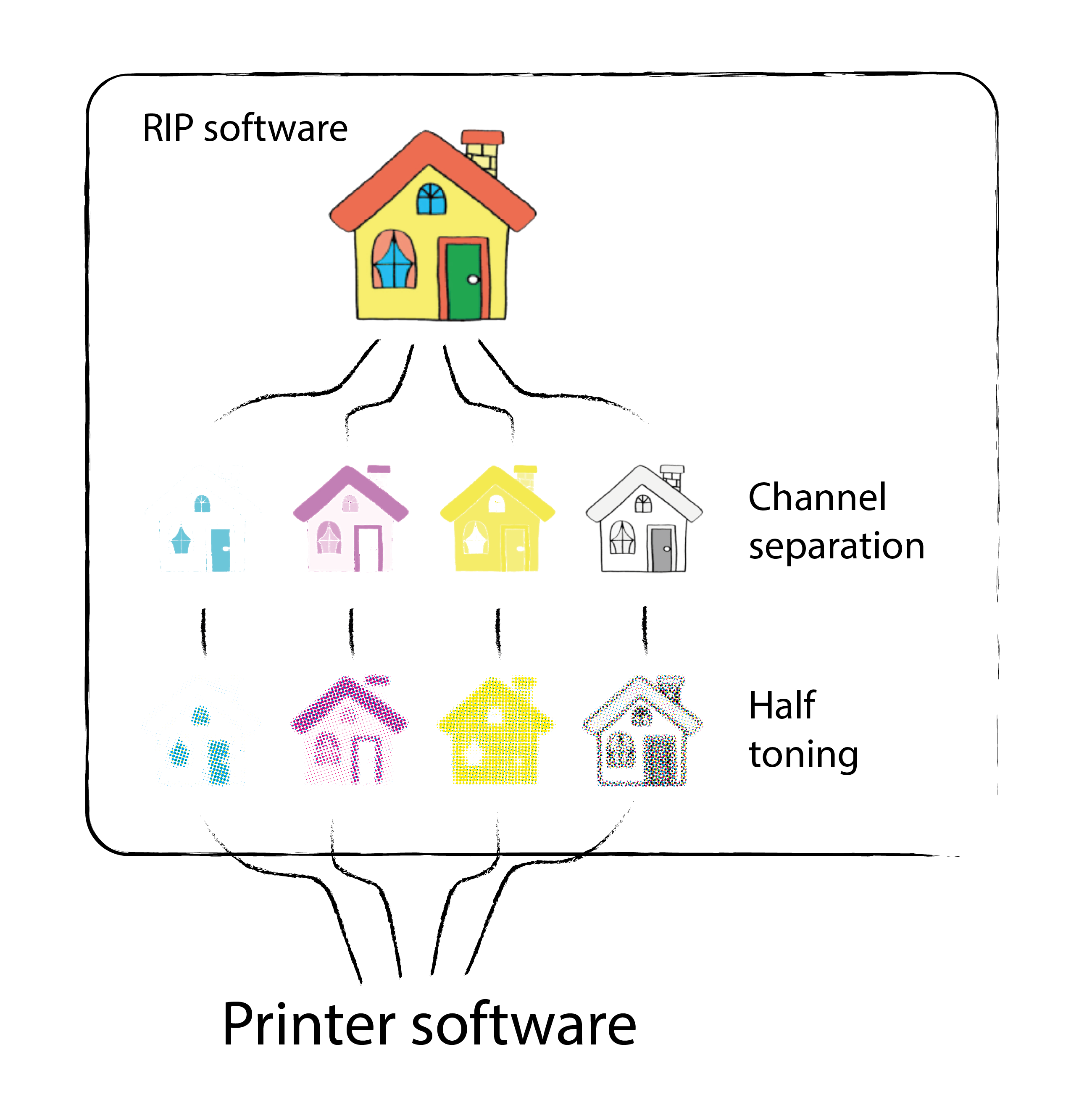

The data is taken or received by the RIP software, via files or networks, and consists, as input of the “Printer software”, of the data of the design that you want to print, already separated by color channels (the inks), half toning, and to a correct number of bits per pixel for the desired printing mode.

To design a printer the client must develop a program (Printer software) composed of different sections:

• Machine automation: movement, automatic head cleaning, media management, etc.

• User interface: to manage human/machine interaction (commands, states, diagnostics)

• Datapath: heart of the printing system for image data processing

The section of the Printer software that deals with the processing of print data (Datapath) receives as input the color “plan” for each ink loaded into the printer.

Scanning Technology

This data must be separated into passes according to all definable printing modes, in order to achieve the resolutions (quality) and coverages (saturation) necessary for the application sector. It must also be configurable to flexibly support a variable number of colors and heads per colour, allowing the system to be “scaled” according to the needs and production performance required.

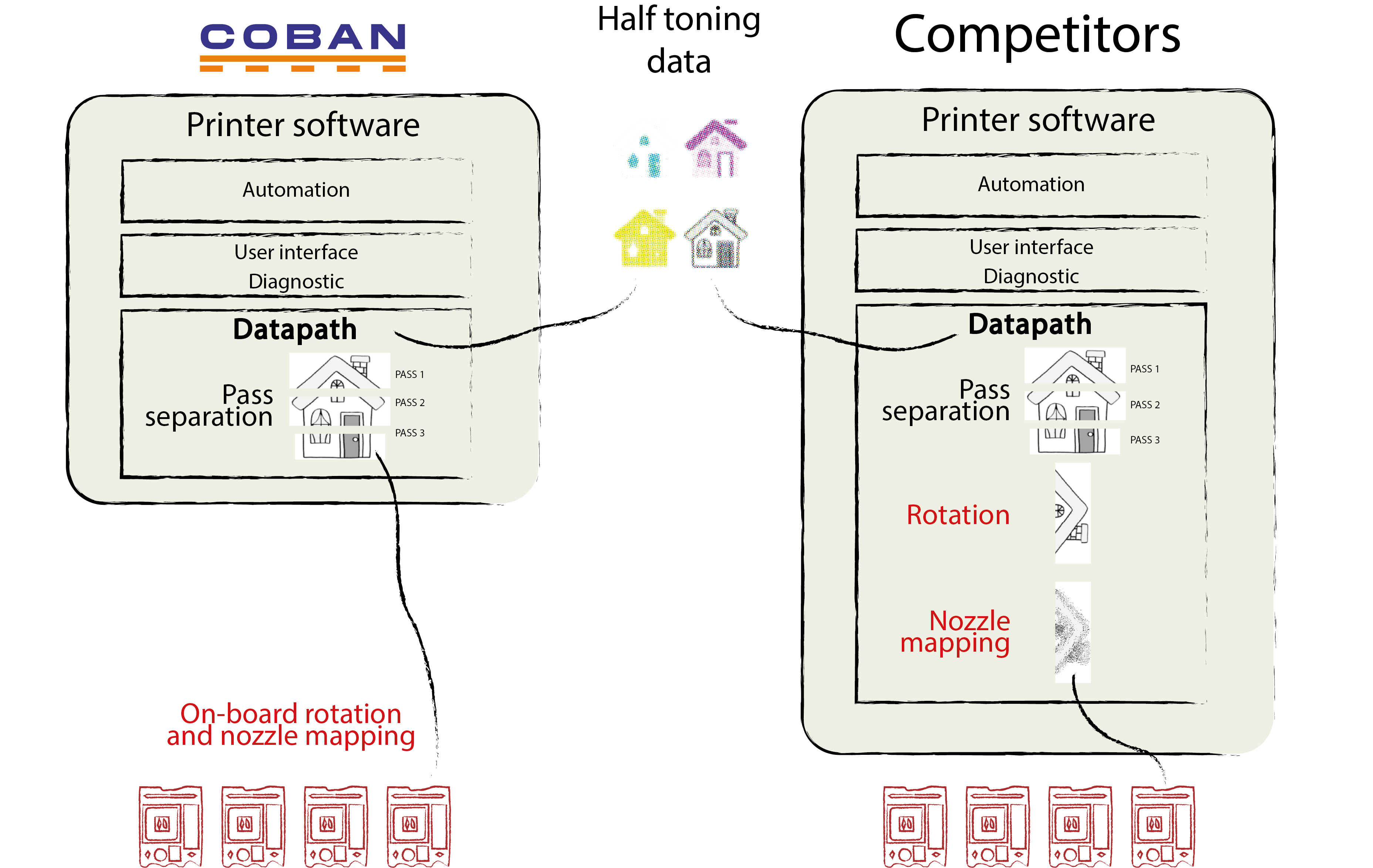

Once the data has been prepared as “print passes”, the Printer software must send it in real time to the cards that control the heads and subsequently carry out the movement of the mechanics. However, to be adequately printed, this data must be rotated and positioned (scramble or nozzle mapping, depending on the geometry of the heads).

Our idea

The COBAN SDK solution provides on-board rotation and scramble, the data does NOT need to be pre-processed.

This allows you to:

• Significantly reduce the complexity of the integration software

• Accelerate integration times

Characteristics

References

Coban technologies have existed in the digital printing market for many years.

The installed fleet is present in many machines of the following companies:

Single Pass Technology

This data must be processed and distributed on the cards that manage the different inks present in the printer, in order to obtain the correct colors with the coverages (saturations) desired depending on the application market. Once the data of a design has been loaded onto the cards, the Printer software only needs to activate the printing process and monitor its continuation. The encoder signal synchronized with the media is read by the cards which will proceed with the printing and repetition of the drawing independently, according to the initial settings requested by the Printer Software. To be adequately printed, however, this data must be positioned (scramble or nozzle

mapping, depending on the geometry of the heads).

Our idea

The COBAN SDK solution provides on-board rotation and scramble, the data does NOT need to be pre-processed.

This allows you to:

• Significantly reduce the complexity of the integration software

• Accelerate integration times

Characteristics

References

Coban technologies have existed in the digital printing market for many years.

The installed fleet is present in many machines of the following companies: